understanding cascade impaction and its importance for inhaler testing|cascade impaction variability : custom Over the lifecycle of an orally inhaled product (OIP), multi-stage cascade impactor (CI) measurements are used for different purposes and to address different questions. Full . The Betfair Acca Edge is the ultimate acca benefit. We take a look at everything that acca edge includes and how you can use it to get the best return from each of your bets .

{plog:ftitle_list}

WEBEnjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

The use of A3G instrument to conduct Aerodynamic particle size distribution (APSD) test of Glaxo Smith Kline's Flovent, which is an orally inhaled suspension, and the data offers hope of achieving unprecedented level of drug recovery (Mass Balance) in comparison with manual analysis . The purpose of this article is to catalogue in a systematic way the available information about factors that may influence the outcome and variability of cascade impactor . Over the lifecycle of an orally inhaled product (OIP), multi-stage cascade impactor (CI) measurements are used for different purposes and to address different questions. Full . The purpose of this review is to discuss the roles of cascade impactor (CI) data in inhaler assessment and to examine the relationship between aerodynamic particle size .

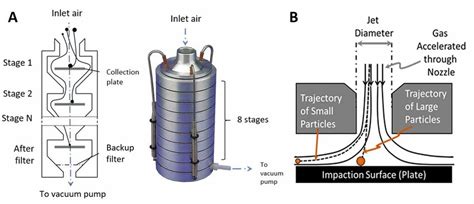

Three distinct attributes set cascade impaction apart from all other particle sizing techniques in terms of relevance for orally inhaled products (OIPs): (1) The ability to generate .Understanding how cascade impaction works and how to mitigate variability ensures that measured data are robustly fit for purpose. Out-of-specification (OOS) results compromise . Cascade impaction size fractionates a dose on the basis of particle inertia, generating a series of samples that are subsequently analyzed, typically by HPLC, to produce an APSD specifically for the API 11. A key . The multi-stage cascade impactor (CI) is widely used to determine aerodynamic particle size distributions (APSDs) of orally inhaled products. Its size-fractionating capability depends.

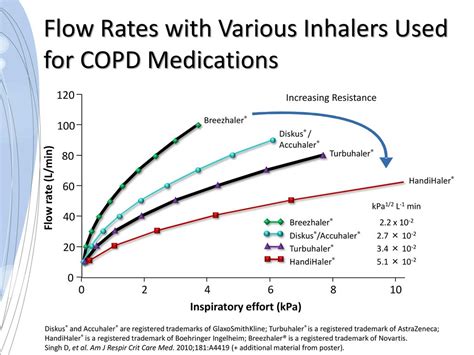

Cascade impaction is the primary analytical method used to assess the performance of inhalation products. It permits capture and chemical analysis of different size . Multi-stage cascade impactors (CIs) are the preferred measurement technique for characterizing the aerodynamic particle size distribution of an inhalable aerosol. Stage .Minimizing Variability of Cascade Impaction Measurements in Inhalers and Nebulizers . Induction Port The induction port (IP) is important for MDI testing due to the need to capture the ballistic component separately from the fraction . The choice of a suitable viscous surface coating to avoid particle bounce in a CI [79][80][81][82] is of critical importance when testing DPIs [83,84], with the exception of the MSLI, where the .

4. M. Copley, “Understanding cascade impaction and its importance for inhaler testing,” whitepaper, accessed Jul 28, 2014. 5. CSA Group Standard, CAN/CSA-Z264.1-02 (R2011) “Spacers and Holding Chambers for Use with Metered-Dose Inhalers,” (Canadian Standard Association, 2011). 6. M. Although nasal inhalation products are becoming more and more important for the delivery of medicines, characterization of these products for quality control and assessment of bioequivalence is complicated. Most of the problems encountered are associated with the assessment of aerodynamic droplet/particle size distribution (APSD). The droplets produced .

The purpose of this article is to catalogue in a systematic way the available information about factors that may influence the outcome and variability of cascade impactor (CI) measurements of pharmaceutical aerosols for inhalation, such as those obtained from metered dose inhalers (MDIs), dry powder inhalers (DPIs) or products for nebulization; and to suggest .Aaps Pharmscitech, 2008. The purpose of this article is to catalogue in a systematic way the available information about factors that may influence the outcome and variability of cascade impactor (CI) measurements of pharmaceutical aerosols for inhalation, such as those obtained from metered dose inhalers (MDIs), dry powder inhalers (DPIs) or products for nebulization; .try approach to the use of the MB from a CI test. To meet the need for consistent guidance on CI measurements, the Working Group undertook to: (a) Identify points to consider in the develop-ment of cascade impactor methodology (b) Address points to consider during set-up and operation of a cascade impactor for testing In its raw form cascade impaction data is less than optimal for assessing the likely success of drug delivery, or batch-to-batch equivalence. . with other, often product-specific stage groupings adding detail. However, our collective understanding of how best to analyse cascade impaction data continues to evolve. . Inhaler Testing Academy

Diagram of the apparatus. A cascade impactor measures the reach range of a particulate substance as it moves through an opening with the use of aerosol.Cascade impactors are strictly measurement-related devices. In addition to measuring the range of substances moved through an opening by aerosol, the impactor can also be used to determine the particle size of the . This test, employing the Next Generation Impactor (NGI), has become indispensable for developers and manufacturers, particularly in the domain of dry powder inhalers (DPIs). Its importance cannot .Understanding cascade impaction and its importance for inhaler iesting. Contact Us Today . Register your interest: Inhaler Testing Academy . Pharmaceutical Testing (e.g. testing of tablets, capsules, powders, semisolids, suppositories) Detergent Testing.

The standard method for measuring the APSD of inhaler products is the cascade impactor, included in international pharmacopoeias, which can differentiate the aerodynamic particle size measurement .Introducing a new approach for dry powder inhaler characterisation, which combines automated imaging and cascade impaction to measure the particle size and shape distributions for particles which have been aerosolized. This aids understanding of the dispersion of the formulation during device actuation. The actuator has been the patient interface of the metered-dose inhaler for the past 50 years. The original 1956 design remains a significant influence upon today's actuators and, moreover, its .

OIP Quality Metrics Based on Aerodynamic Particle Size Distribution. The general goal of inhaler product QC testing is to provide additional assurance and confirmation that a batch of inhalers is of acceptable quality ().Aerodynamic particle size distribution (APSD) measurements are undertaken by cascade impaction (CI) to quantify the aerosol particle size . Copley Scientific, the world’s leading manufacturer and supplier of inhaler test equipment, has released two new educational animations that provide a clear, easy to understand introduction to critical aspects of inhaled .Mass balance is useful in determining whether an expected mass of drug has been captured by the impactor to provide a reliable measurement of the APSD, but by itself does not ensure that theAPSD results are valid. APSD . In the testing, inhalers were actuated to deliver the drug substance through a simple induction port or an MT model to a cascade impactor to separate aerosolized particles of different densities .

dsa hard drive test system x3550

Over the lifecycle of an orally inhaled product (OIP), multi-stage cascade impactor (CI) measurements are used for different purposes and to address different questions. Full-resolution CIs can provide important information during product development and are widely used but are time- and resource-intensive, highly variable, and suboptimal for OIP quality . The understanding and awareness of all these factors should aid in the development of optimized CI methods and appropriate quality control measures for aerodynamic particle size distribution (APSD .22nd August 2016; Nottingham, UK: Copley Scientific, the world’s leading manufacturer and supplier of inhaler test equipment, has released two new educational animations that provide a clear, easy to understand introduction to critical aspects of inhaled product testing. The videos, entitled ‘How does a cascade impactor work?’ and ‘System for improved in vitro-in vivo .

Christopher D, Curry P, Doub B, et al. Considerations for the development and practice of cascade impaction testing including a mass balance failure investigation tree. J Aerosol Med. 2003; 16 :235–247. doi: 10.1089/089426803769017604.It is necessary to characterise the dose delivered. The delivered dose should be consistent with the label claim, have low batch to batch variation and must be stable through-life (for example, for a multi-unit dose product, it is necessary to confirm that actuation 1 is the same as actuation 100).

Today, we're diving into the fascinating world of cascade impaction data, specifically focusing on how we measure the performance of orally inhaled products (OIPs). Cascade impaction isAPSD of Soft Mist Inhalers (SMIs) For SMIs as for nebulisers, the evaporation of droplets exacerbated by the thermal mass of the impactor can be a problem.Loss of solvent reduces droplet size, producing artificially low APSD measurements, compromising the integrity of the resulting data.Cooling the impactor to approximately 5°C is the recommended method for .2 March 2017; Nottingham, UK: Copley Scientific, the world’s leading manufacturer of inhaler test equipment, has upgraded its Sample Preparation Unit (SPU) Model 2000 to include a modified induction port fixture with a view to further broadening its appeal.The upgraded SPU 2000 now accommodates a Fluticasone Propionate/Salmeterol Xinafoate (FP/SX) induction . cascade impaction include the 8-stage Anderson cascade impactor operated at 28.3 L/min, the 5-stage Marple-Miller impactor operated at 60 L/min, and the 7-stage next gener -

multistage cascade impaction

flow rate variability inhaler

cascade impaction variability

WEBO Iguatemi é o Shopping da sua vida. E aqui, no maior ponto de encontro da cidade, as famílias de Fortaleza encontram tudo. São mais de 450 lojas e quiosques que reúnem o mais completo mix de compras, lazer, gastronomia e serviços de Fortaleza em mais de 90 mil metros quadrados. Distribuídos por corredores amplos e projetados para o .

understanding cascade impaction and its importance for inhaler testing|cascade impaction variability